Selenium Dioxide: Commentary on Its Scientific and Practical Importance

Historical Development

Selenium dioxide first started turning heads in chemistry circles more than a century ago. Scientists saw value in the element selenium, tucked between sulfur and tellurium in the periodic table, especially after Berzelius flagged it in the early 1800s. Not long after, selenium dioxide found use as an oxidizing agent, marking its place in laboratory tool kits. I remember hearing stories from chemists who worked in dye manufacturing in the early 20th century—the introduction of selenium compounds improved synthetic processes they relied on. This chemical’s path mostly traces industrial growth where improvements in glassmaking, pigment production, and analytical work needed a stable, robust oxidizer.

Product Overview

Selenium dioxide steps up as an important inorganic compound. The typical supply comes as either a white, crystalline solid or a fine powder, making it handy for both lab experiments and bulk industrial applications. Markets have no shortage of suppliers offering technical, reagent, and even electronic device grades, each with its own trace impurity profile and grain size. A smell similar to decayed horseradish meets you while opening the container, and anyone working with it quickly learns to keep the bottle tightly closed.

Physical & Chemical Properties

Selenium dioxide’s most telling physical features include its white or sometimes off-white appearance, rather sharp odor, density of about 3.95 g/cm³, and a melting point near 340°C. Those who have heated it in a lab recognize the moment it sublimes—turning directly from solid to vapor and forming needle-like crystals upon cooling. Selenium dioxide dissolves readily in water, yielding selenious acid, and in organic solvents like ethanol. Its strong affinity for moisture often causes it to clump up if left unsealed. In terms of reactivity, this compound shows a remarkable ability to oxidize organic substrates, a property that synthetic chemists value deeply. Many oxidation chemistry breakthroughs have leaned on SeO₂’s solid, repeatable results.

Technical Specifications & Labeling

Technical documentation spells out selenium content with tight minimums, usually over 99% for reagent grade. Analyses also flag heavy metal contaminants like arsenic and lead, especially given selenium’s toxicity, and solid protocols exist for batch testing. Drum and bottle labels note UN number 2630, hazard pictograms, and recommended storage temperatures. Regulatory docs highlight personal protective equipment like goggles, gloves, and full ventilation—laboratories and factories both adhere to standard GHS (Globally Harmonized System) symbols. From all this, it’s clear: a slip in labeling or storage can bring serious risks.

Preparation Method

Most commercial selenium dioxide comes from careful oxidation of elemental selenium. Factories burn selenium metal with excess oxygen or simmer it in concentrated nitric acid. The process gives off selenium dioxide fumes, which workers channel and condense into solid form. In a more lab-focused setting, oxidizing selenium using hydrogen peroxide or bromine water can produce smaller quantities with high purity. I recall graduate research projects where crystal purity meant the difference between useful and useless research data; the best outcomes depended on keeping temperatures and flow rates flawless from start to finish.

Chemical Reactions & Modifications

Selenium dioxide shines as an oxidizer in organic chemistry—particularly during allylic oxidations. For example, SeO₂ converts cyclohexene into 1,2-cyclohexanedione with high selectivity. Chemists love that—clean conversions make for less time wasted on after-the-fact purifications. SeO₂ also reacts with primary and secondary alcohols, aldehydes, and certain aromatic compounds, generating products key to pharmaceuticals, fragrances, and pigments. Chemical suppliers sometimes modify it for specialized reactors by embedding it in silica or clay, which helps contain dust and aids slower, more controlled oxidations. Such setups keep workflows safe and efficient even in scaled manufacturing environments.

Synonyms & Product Names

Around the world, suppliers and researchers alike recognize selenium dioxide by various names, which can sometimes trip up newcomers. Common synonyms include selenious oxide, selenium(IV) oxide, and even selenium anhydride. In different languages and catalogues, folks meet it as “dioxido de selenio” or “Selendioksid.” Product codes like SeO2, 7783-00-8, and EC 231-956-9 help bridge the naming gap. Such diversity in terminology comes from the global spread of scientific research and industrial applications, so cross-referencing datasheets is not just smart, it’s essential.

Safety & Operational Standards

Selenium dioxide demands respect in any workplace, and not just because of its pungency. It’s classed as hazardous by OSHA and the European Union. Direct contact with skin or eyes spells trouble—irritation mounts rapidly. Even inhaling the dust at low levels can upset the respiratory tract. Chronic exposure brings long-term toxicity, including danger to internal organs like the liver and lungs. Workplaces need tight fume hoods, particle-filter masks, chemical-resistant gloves, and strict waste handling protocols. Emergency clean-up kits lie ready in corners of most labs and factories dealing with selenium compounds. For me, remembering the sharp, lingering odor in a research lab lab used to be a cue to check nearby ventilation fans.

Application Area

Selenium dioxide leaves its mark across diverse industries. In organic synthesis, it’s often in the oxidation step, particularly in pharmaceutical labs and specialty chemical manufacturing. Glassmakers use it to counteract the green tint iron gives to glass, making crystal glass clearer. In colorant and pigment production, it tweaks hue properties that would be tricky to reach using other additives. Selenium dioxide also factors into the electronics field, playing roles in special ceramic and glass formulations for semiconductors. I saw colleagues in material science lean on SeO₂ for preparing photoconductors and photovoltaic prototypes—a reminder that practical science often needs a material that’s both reliable and consistent.

Research & Development

Chemists and engineers keep finding new spots for selenium dioxide in advanced research. Recent projects dig into supported selenium dioxide catalysts for pollution control, cutting down nitrogen oxide output from engines. Some research teams blend it into frameworks for designing selective organic transformations, reducing waste that used to be seen as an unfortunate cost of progress. Nanotechnology investigations now look at selenium dioxide nanoparticles in biosensors or even in targeted drug delivery, exploring the limits of biocompatibility without sidestepping the toxicity challenge. These breakthroughs flow from a simple principle: every industry wants a safer, more efficient route from raw material to final product.

Toxicity Research

Toxicologists don’t look lightly at selenium dioxide. Research lines up robust data showing respiratory, hepatic, and renal impacts at relatively low exposure levels. Repeated handling or poor ventilation quickly leads to toxic buildup in workers, which is why regulatory authorities like NIOSH and the EU set exposure limits down to fractions of a milligram per cubic meter. Animal studies link selenium dioxide dust to cellular changes and oxidative stress. Ongoing public health research stays vigilant for cases of accidental poisoning or environmental release, especially near chemical processing plants. Teaching proper handling and fast intervention stands as the best defense against selenium’s toxic side—it’s more than a regulatory checkbox; it’s about keeping the workplace safe and the local environment clean.

Future Prospects

Attention on selenium dioxide won’t fade soon. Driven by cleaner manufacturing and environmental controls, research aims to widen its use while dialing back risks. Safer packaging, alternative formulations, and better waste handling protocols grow more commonplace as industries respond to tighter regulations. Emerging fields in green chemistry hunt for catalysts that use selenium dioxide more efficiently, sometimes immobilizing it for less environmental fallout. I’ve watched environmental science conferences highlight remediation technologies tagging selenium oxides for heavy metal removal from waterways. Startups experiment with micro-scale applications, including medicine and nano-structured electronics, careful to keep an eye on both efficiency and safety. Where technology reaches for smaller, cleaner, faster processes, selenium dioxide’s unique chemistry promises to play a role—so long as safety and sustainability keep pace.

Understanding Where Selenium Dioxide Fits In

Anyone looking for a powerful oxidizing agent will likely cross paths with selenium dioxide. The stuff comes as a white, crystalline powder, and it doesn’t get much press outside specialist circles. Yet, it holds a serious spot in chemistry, industry, and even in the lab tricks of organic chemists. I’ve seen firsthand how a small container of this powder can change the outcome of a complex reaction.

Selenium dioxide’s ability to add oxygen atoms to other molecules opens doors in both research and manufacturing. Walk into a fragrance lab, and you’ll see technicians reaching for selenium dioxide when they need to nudge raw cinnamon oil into cinnamaldehyde — the backbone of what we smell when we think “cinnamon.” This small step carries a scent through perfumes and even into food-grade extracts.

Industry Uses Reach Far Beyond the Lab

The glass industry counts on selenium dioxide for another kind of magic. Anyone who’s ever noticed pink-hued glass, especially in architectural features or collectibles, has selenium dioxide to thank. Chemists learned that this compound can neutralize the green tint caused by iron in glass. Add just a dash of selenium dioxide while the glass is still molten, and out comes a pleasing, non-green clarity. It’s a clever workaround, born from necessity and perfected by years of trial and error.

Metals refining brings another layer of importance. Electrolytic manganese production, for example, can suffer from impure results if selenium dioxide isn't part of the process. In these factories, workers toss in selenium dioxide to strip out unwanted elements and deliver high-purity metal ready for batteries and steel. Skip it, and the end product buckles under modern demands.

Why Chemists Keep Turning to Selenium Dioxide

In the realm of organic chemistry, few oxidizers offer the balance of selectivity and strength found here. Need to turn an alcohol into an aldehyde, but keep the rest of the molecule just so? Selenium dioxide goes to work, cutting down development time and boosting reliability. I remember the relief during graduate research, spotting a clear reaction after weeks of dead ends with other chemicals.

Textile industries even use this compound to treat polyester fibers, sometimes enhancing their dye uptake or adding functionality. While it doesn’t make headlines like other finishing agents, manufacturers swear by it to achieve precise shades and performance benchmarks.

Safety, Challenges, and Smarter Handling

There’s no escaping the darker side of selenium dioxide: toxicity. The compound gives off pungent fumes and causes serious health problems if mishandled. I learned early to respect its dangers. Gloves, goggles, and fume hoods aren’t suggestions—they’re requirements. Anyone who works around the compound knows that storing and disposing of it takes just as much care as using it in the lab.

To keep workers and communities safe, regulators keep close tabs on selenium compounds. Federal agencies in the US and Europe set limits for workplace exposure, and disposal rules prevent contamination of soil and water. This makes it even more important to close the loop on chemical handling—spending more on leak-proof packaging or tracking systems isn’t “extra”; it’s good sense.

Looking Forward With Responsibility

Research teams search for greener oxidizers and safer replacements, but selenium dioxide continues to solve real problems today. Better ventilation, training, and monitoring have lowered risks in labs and plants. Training isn’t just policy—sharing real stories about missteps helps keep the next chemist safer. We keep learning, because chemistry doesn’t just stay in textbooks—it walks into every product, every workplace, every moment of careful planning.

What Makes Selenium Dioxide Stand Out?

Selenium dioxide isn’t a household name, but it pops up in various industries. It serves as a reagent in laboratories, helps tint glass, and finds a use in electronics. In chemistry classes, sometimes teachers talk about it for its strong oxidizing properties. But with any substance that has punch in its reactions, it’s good to ask if it’s safe to handle.

Getting to Grips with the Hazards

If you run a web search about selenium dioxide, words like “toxic” come up a lot. The reason lies in how the compound acts on living bodies. Breathe in the dust, and irritation soon follows—a burning in the nose and throat, coughing, even shortness of breath. Swallow some, and nausea, vomiting, or diarrhea could pull up a chair at the table. There’s something serious here: even small amounts raise a real risk. Long exposure gets even uglier, leading to damage in organs such as the liver and nervous system. In animal studies, selenium compounds harmed reproduction, so these dangers aren’t just talk.

People who work where selenium dioxide gets used—like in glass making or electronics repairs—face the most direct danger. Gloves, goggles, and well-ventilated spaces matter. Safety data sheets show up before anyone gets started because rules can’t be bent when health takes a hit. Even after work, folks can carry dust on their clothes; families might end up exposed if washing routines slip.

Why Dose Matters More Than Just the Name

Not everything labeled “toxic” will cause problems in tiny doses. Our bodies actually require selenium, but in small, controlled amounts as part of our diet. The catch with selenium dioxide is how it tips the balance. Go above that fine line, and the body can’t keep up. This is a classic case of “the dose makes the poison.”

Some of us who spent time in chemistry labs remember handling strong-smelling powders behind glass shields, not just for show but because some compounds are unforgiving. Once, a cloud of selenium dioxide escaped during a reaction; eyes started watering, even with fans pulling air out. That memory sticks.

Environmental Footprint and the Community

Selenium dioxide doesn’t just stop with hurting people. It rides air currents, landing in water and soil. When it gets washed into rivers, it sinks into the food chain. High amounts in fish or livestock spread upwards, eventually landing on dinner plates. Known outbreaks in some U.S. states left birds and fish dying, and local families had to avoid water sources until it cleared.

How to Stay Safe and Limit Harm

Rules protect workers and the environment, but cutting corners can happen in places with less oversight. Education stands in the way of short-term savings leading to lasting problems. Emergency material safety meetings, up-to-date protective gear, and regular monitoring make a difference. Community involvement keeps companies honest; local watchdogs test soil and water, post findings, and push for action if things look risky.

Practical Steps for a Safer Approach

Ventilation in workspaces, real training sessions, and better cleanup methods lower risk. Proper disposal keeps selenium dioxide away from landfills or sewers, keeping it out of water tables. If someone feels sick after handling the stuff, immediate medical help matters—waiting could anchor long-term harm. Sharing stories, lessons learned, and updates within industries helps new generations avoid old mistakes.

Storing a Powerful Chemical Without Cutting Corners

Selenium dioxide grabs attention for its wide use in industry, research, and even niche manufacturing processes. Working with a compound like this demands a lot of respect for safety practices. I remember handling chemicals during my college days, and nothing sticks with you like a lesson learned from a near miss—one time, a peer barely avoided a spill just by following a label’s storage instructions to the letter. With selenium dioxide, there’s no margin for error.

The compound gives off a sharp odor, almost reminiscent of decaying horseradish. It signals trouble long before most other lab chemicals would. This isn’t just an annoyance—the vapor is quite toxic. Scientists have traced links between airborne selenium compounds and serious health effects, especially on the respiratory system. For those reasons, you never stash this substance on an open shelf or in a corner of a workbench. Reliable storage starts with choosing airtight, corrosion-resistant glass or certain plastics. I’ve seen laboratories mistakenly use cheap containers that degrade after months; only high-grade borosilicate or compatible polymers pass the test after repeated exposures.

The chemistry also reacts badly to moisture. Selenium dioxide shifts from a solid to an acidic solution with water. Unwanted reactions can spiral out of control—years ago, one small leak in a university lab corroded a shelf and threatened to eat through the floor. To keep things dry, storage rooms rely on desiccators or added silica gel packs, which soak up stray humidity. Some labs run regular checks to swap out saturated drying agents, making the storage process far more proactive than reactive.

Keeping Everyone Protected Beyond the Basics

Labels aren't just bureaucratic red tape. If a container’s seal gets cracked or broken, people need information fast—a clear hazard label and emergency procedure card offer that guidance within seconds. After talking with several industrial hygienists, I learned how much strain a poorly labeled shelf can place on coworkers in a high-pressure moment. It’s worth taking the extra step to log each move in a chemical inventory system so nothing slips through the cracks.

Ventilation ranks high on the list. Handling selenium dioxide sometimes produces vapors, so fume hoods and ducted exhausts aren’t optional extras; they form the shield between a researcher and an unexpected exposure. For smaller research teams, portable air purifiers and regular filter replacements play supporting roles. Even with all these safeguards, staff training makes the difference. Handling instructions sink in best as hands-on walkthroughs, not online modules.

Safe Practices That Pay Off

Disposal causes headaches since selenium dioxide can’t just go in the trash. Special hazardous waste containers send material for secure incineration through certified contractors. Accidental releases or spills demand quick action with spill kits—neutralizing agents, protective gear, and easy access to eyewash stations take priority. Over the years, people learn that rehearsed drills speed up reactions and keep panic at bay.

Complacency feels tempting once routines take root, but the dangers posed by chemicals like selenium dioxide don’t take breaks. The institutions that set the gold standard always push for spot checks, retraining, and honest incident reviews. Each layer of caution—proper containers, humidity-proof storage, clear labeling, effective ventilation, rigorous training—adds years of safety for workers and peace of mind for anyone who shares the facility. These aren’t just workplace policies; they become habits that stick for life.

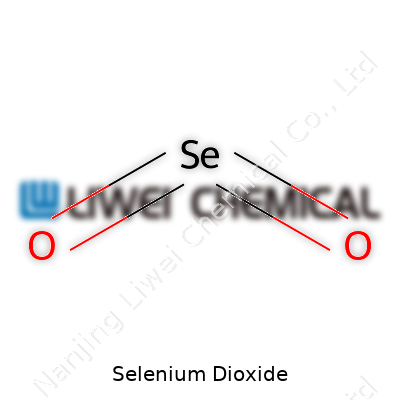

Behind the Symbol SeO2

Selenium dioxide, written as SeO2, may not catch much attention unless chemistry pops up at a dinner table or in the middle of a science class. Still, you’d be surprised where this white, crystalline solid turns up. Think of glass manufacturing, producing colorless glass or giving it that deep red shade, and you land on selenium dioxide. I remember learning this in college over a late-night session, marveling at how a simple formula—just selenium and oxygen—could play a key role in shaping things around us. The formula itself stands for two oxygen atoms partnered with one selenium atom, nothing tricky, just basic chemistry. Yet, this little combination matters in big ways.

Everyday Uses and Environmental Concerns

Selenium dioxide goes beyond academic notes scribbled in a lab book. This compound helps refine glass and even works its way into the world of organic chemistry as an oxidizing agent. Crafting certain drugs or fragrances often involves SeO2 in the lab, doing its job to tweak molecules for specific effects. Even though those roses in the vase may owe some fragrance development indirectly to SeO2, most people would never trace it back to this white powder.

There’s a flip side. Industries that handle selenium dioxide have their hands full with safety rules. Selenium, in higher doses, crosses the line from helpful to hazardous. Breathing in SeO2 dust causes health issues. Long-term exposure messes with the respiratory system and can damage internal organs. Environmental spills create headaches for communities and regulators. Years ago, a plant in the Midwest ran into trouble after a spill during a routine transfer. The effects stretched beyond the factory fence, hurting soil and water in the area.

Why Accurate Chemical Knowledge Matters

Mistakes with formulas spell trouble—literally and figuratively. Think about someone blending chemicals in a facility. Recording SeO2 as SeO or SeO3 throws things off quickly. Products don’t behave as expected, safety protocols break down, and even small errors rack up big costs. Schools and universities run safety courses for a reason, stressing the importance of memorizing chemical formulas. I still remember a close call in a student lab, where a misread formula led to an unplanned reaction and an emergency cleanup. Precision has more weight in chemistry than anywhere else I’ve experienced.

Responsible Use and Solutions

Companies turning to selenium dioxide face the challenge of balancing usefulness with safety. Strong employee training goes a long way here. Requiring protective gear and updated handling procedures matters. Environmental agencies need to keep a close watch with routine inspections and support for quick spill response. On the tech side, engineers keep improving filters and containment systems, blocking as much SeO2 from reaching the outside world as possible. Research into greener production methods is picking up speed in different countries. A better track record starts with transparency—clear labeling, proper documentation, and regular audits by outside experts.

So, SeO2 packs more into its simple skin than most folks realize. The story behind that formula reaches from classrooms to glassworks, from the smell of flowers to the heart of modern manufacturing. Responsibility and respect for the risks keep it useful, instead of dangerous, making all the difference in how we live and work.

Everyday Perspective on Lab Hazards

Anyone who’s worked in a science lab remembers the odd smell of selenium dioxide—acrid, sharp, and nothing you’d sneak a second whiff of. People often miss the fact that harsh-smelling chemicals can leave more than just an odor; they can pose real health risks. Handling waste like selenium dioxide is more than scribbling down a label and dropping it in a bin—it calls for serious, step-wise attention. Even a tiny amount can harm lungs or skin and leave its mark on waterways downstream.

The Impact on People and Places

Why treat selenium dioxide with such care? Look at the facts: Inhaling its dust can scar lung tissue. Splashing it on skin may cause burns. Letting selenium compounds slip into soil, rivers, or community sewers doesn’t just cloud someone else’s water; it builds up in food chains, harming fish, wildlife, and eventually, food supplies. In some rural areas, selenium has leaked into crops and reduced livestock fertility. Exposure can go unnoticed, but effects drag on, especially for those who work around it.

Responsibility Starts in the Lab

Disposal of selenium dioxide shouldn’t feel like a chore; it’s about respect—for your co-workers, neighbors, your own lungs. No one should risk dumping leftovers down the drain or tossing contaminated gloves in open trash. The right answer always points back to hazardous waste procedures, spelled out by local regulations. Most labs partner with licensed waste handlers. These professionals collect, label, and neutralize waste before it has the chance to seep into groundwater or air.

Personal protective equipment does more than impress safety inspectors. I’ve seen nitrile gloves balloon from exposure; I don’t go near this stuff bare-handed, nor should anyone else. Eye shields, lab coats, and a proper fume hood form a barrier. Years ago, a splash at my old workplace sent a younger technician to the doctor for burns that lingered. A fume cupboard and sealed containers might seem like overkill until you’re the one rinsing a chemical burn.

Simple Steps, Big Results

The safest route sits inside three ideas: label everything, keep it tightly sealed, and document every gram. Even a minute error—wrong container, sloppy handwriting—can send toxic vapor through a facility or block a waste handler’s workflow. Store selenium dioxide waste far from acids and bases, as reactions release dangerous gas. Move it only in secure, approved containers. Don’t try to improvise neutralization with household cleaners or guess at environmental rules.

Local hazardous waste facilities serve as the main hub for proper disposal. Most urban areas run scheduled collections for lab and industrial waste. Staff know how to keep storage legal and safe, tracking shipments the whole way to final processing. Before calling a handler, check federal and local guidelines—especially in schools and small businesses—since disposal routes (and fines for mistakes) can surprise even experienced chemists.

Better Habits for a Safer Community

Curiosity and efficiency push research, but safety must keep pace. People who handle selenium dioxide should remind coworkers to report spills and practice periodic training. Sharing personal stories about mistakes or narrow escapes drives the point home better than slides on a screen. In the end, it comes down to respect—for science, for the world around us, and for the people next to us at the bench.

| Names | |

| Preferred IUPAC name | Selenium(IV) oxide |

| Other names |

Selenium(IV) oxide

Selenium oxide Selenium dioxide (SeO2) Selenium peroxide |

| Pronunciation | /siˌliːniəm daɪˈɒksaɪd/ |

| Identifiers | |

| CAS Number | 7446-08-4 |

| Beilstein Reference | 1203072 |

| ChEBI | CHEBI:30443 |

| ChEMBL | CHEMBL1377 |

| ChemSpider | 55813 |

| DrugBank | DB11131 |

| ECHA InfoCard | 100.029.024 |

| EC Number | 231-957-4 |

| Gmelin Reference | Gmelin 1205 |

| KEGG | C02325 |

| MeSH | D011141 |

| PubChem CID | 24007 |

| RTECS number | VS7520000 |

| UNII | KN7B71U8Q6 |

| UN number | UN1438 |

| Properties | |

| Chemical formula | SeO2 |

| Molar mass | 110.96 g/mol |

| Appearance | White crystalline solid |

| Odor | odorless |

| Density | 3.95 g/cm³ |

| Solubility in water | Soluble |

| log P | -2.0 |

| Vapor pressure | 0.8 mmHg (25 °C) |

| Basicity (pKb) | -1.25 |

| Magnetic susceptibility (χ) | -33.7e-6 |

| Refractive index (nD) | 1.78 |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 57.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | (−114.0 kJ·mol⁻¹) |

| Std enthalpy of combustion (ΔcH⦵298) | -(261) kJ/mol |

| Pharmacology | |

| ATC code | A12CE02 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes severe skin burns and eye damage. May cause respiratory irritation. Toxic to aquatic life. |

| GHS labelling | GHS05, GHS06, GHS08 |

| Pictograms | GHS02,GHS06 |

| Signal word | Danger |

| Hazard statements | H301 + H331: Toxic if swallowed or if inhaled. |

| Precautionary statements | P261, P264, P270, P271, P280, P301+P312, P304+P340, P305+P351+P338, P311, P330, P337+P313, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-0-2-W |

| Lethal dose or concentration | LD50 oral rat 68 mg/kg |

| LD50 (median dose) | LD50 (median dose): 68 mg/kg (oral, rat) |

| NIOSH | NT8050000 |

| PEL (Permissible) | 0.2 mg/m3 |

| REL (Recommended) | 2 mg/m3 |

| IDLH (Immediate danger) | 1 mg/m3 |

| Related compounds | |

| Related compounds |

Selenous acid

Selenic acid Sulfur dioxide Tellurium dioxide |