Nickel Sulfate Hexahydrate: Industry Insights and Directions

Historical Development

Nickel sulfate hexahydrate has played an active role in industrial chemistry since the mid-19th century, tracing roots back to early nickel refining experiments across Europe. Chemists found new methods to extract and purify nickel from ores, searching for efficient compounds that opened doors to wider industrial application. Manufacturers learned to use this nickel salt in electroplating for decorative finishes and corrosion protection on coins, cutlery, and machinery, cementing its spot as more than just an academic curiosity. By the 20th century, the material followed nickels’s path into growing sectors, including batteries and electronics, expanding steadily as manufacturers pushed for better quality and higher purity standards in response to technological leaps.

Product Overview

Nickel sulfate hexahydrate appears as a blue-green crystalline solid that dissolves readily in water. Factories ship it in bulk for plating solutions, battery manufacturing, and occasional pigment work. The product arrives sealed in drums or lined bags, each labeled with batch numbers and production dates for traceability. Many industrial buyers insist on certificates confirming the purity and moisture content. Industrial producers, including well-known chemical giants and regional firms in Asia, Europe, and North America, dominate the market. Most applications prize nickel’s reactivity, letting this salt act as a bridge between raw ore and finished specialty products.

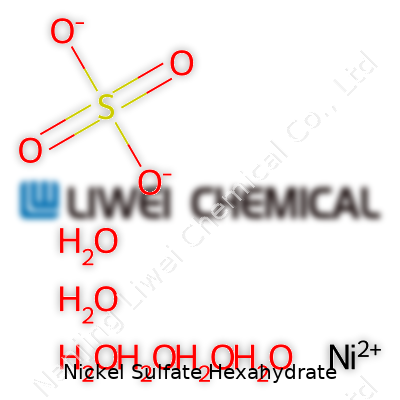

Physical & Chemical Properties

A handful of properties make nickel sulfate hexahydrate stand out. Its distinct blue-green color clues you in to its nickel content. Each molecule contains six waters of crystallization, which explains the solid’s tendency to cake or clump in humid warehouses. It melts near 53°C—surprisingly low for an inorganic salt. In labs, those water molecules come off first, making drying an option but rarely the industrial choice. Dissolved in water, the solid breaks apart smoothly, producing nickel(II) ions and sulfate ions. These ions set the stage for battery cathodes, sensors, and industrial catalysts. Chemically, it reacts with reducing agents, base metals, and a range of organic ligands.

Technical Specifications & Labeling

Specification sheets usually list nickel content at about 22% by mass, with clear upper limits for traces of iron, copper, magnesium, and other troublemakers. Water content sits between 20% and 23%, reflecting the crystalline form. Particle size can vary, but pure bulk material arrives as uniform crystals to support consistent dissolving rates in automated feed hoppers. Labels spell out batch numbers, CAS codes, hazard warnings, and the full chemical name. Unambiguous black and red warnings indicate toxicity and environmental risk, making it tough to mistake this commodity for a harmless blue powder. International shipping rules enforce hazard codes and safety sheets in English or local language as required.

Preparation Method

Factory production takes nickel-bearing ores—often pentlandite or garnierite—and leaches them with sulfuric acid, which pulls nickel ions into solution as nickel sulfate. Older plants sometimes refine crude nickel with air oxidation, but modern sites prefer hydrometallurgical circuits, stripping out impurities through precipitation, solvent extraction, and crystallization. Engineers monitor temperatures and pH closely, since even small shifts can affect yield or lead to unwanted solid byproducts. The final product emerges as damp crystals, which undergo washing, drying, and sieving before packing for sale. Some companies recycle nickel-containing secondary sources, such as battery scrap, to close the loop and ease environmental pressure.

Chemical Reactions & Modifications

This nickel salt steps up to a range of chemical challenges. Lab chemists and battery makers use it to create nickel hydroxide by mixing with sodium hydroxide—key in positive plates for rechargeable nickel-cadmium and nickel-metal hydride batteries. Plant operators mix it with sodium carbonate to yield nickel carbonate, another pigment and catalyst source. In the electroplating bath, nickel ions migrate toward a workpiece and coat it smoothly under the right conditions, enabling control over texture and thickness unseen in early industry. The compound also forms chelates and complexes with organic molecules, while its reactions with phosphates, chromates, and silicates generate specialty ceramics and magnets.

Synonyms & Product Names

Ask a supplier or check a label, and you might see many names referring to the same chemical: Nickel(II) sulfate hexahydrate, blue nickel salt, nickel vitriol, or just “nickel sulfate crystals." International catalogs carry translations or abbreviations, such as NiSO4•6H2O, but industry buyers pay most attention to stated purity and water content, which matter more in practice than the tradition behind a particular label. Some regions add commercial grades in product codes to signify battery-grade, plating-grade, or technical purity, supporting sector-specific demands.

Safety & Operational Standards

Decades of study have made it clear that nickel salts, including this one, require careful handling. Direct contact or inhalation leads to skin rashes and respiratory irritation, while chronic exposure is tied to increased risks of certain cancers, especially among electroplating workers. Factory safety officers drill employees to wear gloves, eye shields, and filtered masks. Emergency procedures focus on spill capture and neutralization, as runoff can endanger water sources and disrupt aquatic life. Regulatory agencies in Europe, North America, and Asia demand strict monitoring of workplace air and water emissions, setting regulatory limits that keep environmental risks in check without forcing plant closures.

Application Area

Nickel sulfate hexahydrate supports a surprising range of trade and manufacturing. Battery manufacturers have seen demand double with the rise of electric vehicles and renewable energy storage, where this compound turns into nickel-rich cathode materials powering everything from cell phones to buses. Electroplating outfits maintain steady use for corrosion-resistant finishing on tools, fasteners, bathroom fixtures, and parts in aggressive chemical environments. Some companies use the compound to grow nickel oxide catalysts, drive dyeing processes for textiles, or produce magnetic ceramics and piezoelectric sensors. Even in more traditional paint and pigment segments, the salt plays a behind-the-scenes role, though more stringent handling rules have narrowed these uses.

Research & Development

R&D investments have migrated toward battery-grade nickel sulfate in recent years, under pressure from electric transportation’s growth. Labs continually push to refine crystal morphology and purity, both of which can affect downstream electrochemical performance and manufacturing yield. Scientists track residual impurities down to parts per billion, since lower iron or cobalt contamination means greater battery life and safety. University groups investigate mechanistic details of ion transport in next-generation cathode recipes, searching for tweaks that boost charging speeds or thermal stability. Media sometimes focus on headline-grabbing breakthroughs in recycling, though commercial-scale recovery of nickel from end-of-life batteries remains a work in progress, especially as battery designs evolve.

Toxicity Research

Public health data underline the need for vigilant control of airborne and waterborne nickel. Decades of epidemiological surveys trace elevated lung and sinus cancer rates to industrial exposure, especially among unprotected plating and plant workers. Toxicologists have mapped DNA and enzyme changes in animal and cell studies, clarifying the links to chronic health issues. Much debate surrounds nickel’s role in allergy formation and immune system suppression, complicating risk assessment for borderline exposures in the general population. Policy groups and industry have responded with stiffer regulations around personal protective equipment, emissions, and process wastewater, alongside increased medical screening for long-serving workers.

Future Prospects

Nickel sulfate hexahydrate stands at the center of technical and environmental conversations as the battery market expands. Battery-grade purity will keep seeing massive upgrades as automakers lock in supply chains that reward both sustainability and reliability. Deployment of stricter environmental rules seems likely, pushing recycling systems and waste minimization up the agenda for leading players. Plant operators are building out recovery networks to reclaim nickel from used batteries, sidestepping supply crunches and cutting embedded emissions. Analysts expect regional growth in Asia and Europe as governments double down on electrification programs, while advanced chemical recycling moves from pilot plant to production line. Innovations focused on less-toxic alternatives for legacy uses, such as pigments or ceramics, will provide new options for sectors concerned with occupational health.

The Backbone of Rechargeable Batteries

You might recognize the buzz around electric vehicles and energy storage these days. Walk into any electronics store or browse online for a smartphone, you’re bound to notice promises of longer battery life. Those claims often trace back to what happens inside battery production plants, where nickel sulfate hexahydrate quietly does the heavy lifting.

Battery makers favor this compound, especially for lithium-ion batteries found in cars and portable electronics, thanks to its critical role in nickel-rich cathodes. These cathodes give batteries higher energy density and longer range. As electric vehicle demand climbs, companies like Tesla and CATL look for reliable sources of battery-grade nickel sulfate. Nickel-based batteries tend to last longer and store more power, solving real-world problems like range anxiety or phones running out of juice too quickly.

Metal Plating and Everyday Electronics

Pull out your house keys, open a kitchen cabinet, or plug in a device — chances are, nickel plating touches your life. This isn’t just about keeping things shiny. Nickel-plated surfaces last longer and fight off corrosion much better than bare metals. Factories use nickel sulfate hexahydrate in electroplating baths, applying thin, smooth metal layers to everything from coins to bolts to doorknobs.

From a health perspective, plating with nickel provides a barrier that shields underlying materials from rust. Consumers expect products to be both durable and safe. In my own kitchen, old utensils with nickel-plated handles often outlast newer, uncoated ones. That’s more than just a coincidence — skilled electroplating, powered by this compound, keeps rust and chipping at bay.

Catalysts in Everyday Manufacturing

Think about old school photography, or dyes that make your shirts pop with color. Even in these mature industries, nickel sulfate works as a catalyst, helping speed up reactions and keep processes efficient. Chemical plants rely on it to synthesize other useful chemicals and specialty products.

Workers must focus on handling this material properly to avoid skin reactions or inhalation risks. Years ago, I saw a safety campaign at a local factory reminding staff about gloves and ventilation. With strong protocols, nickel can remain a trusted teammate in chemical production without endangering people.

Where to Go From Here

As societies demand more electric vehicles, clean energy, and durable products, the need for nickel sulfate hexahydrate keeps growing. Sourcing sustainable nickel matters a lot. Indonesia, the Philippines, and Canada supply much of the world’s stock — but mining often sparks controversy about labor and pollution.

Industry and policymakers have a real opportunity to work together for better mining practices and innovative recycling. For instance, leading tech companies invest in closed-loop programs, reusing nickel from spent batteries. If more manufacturers followed those steps, the environmental strain could shrink.

Education and transparency go hand in hand with safe workplaces and responsible sourcing. Informed consumers can push brands to trace materials back to ethical origins. As I see it, caring about chemicals like nickel sulfate hexahydrate is not just for scientists in labs or CEOs in boardrooms — it matters every time someone charges their phone or starts their car.

Looking Beyond the Lab Shelf: Everyday Connections

Nickel sulfate hexahydrate goes by the chemical formula NiSO4·6H2O. These numbers do more than label a bottle in a chemistry lab. I’ve seen this compound involved in fields from battery manufacturing to metal plating. In some ways, it’s easy to overlook how these simple numbers touch everyday routines.

Understanding the Details

The structure here, NiSO4·6H2O, tells a story. You get one nickel atom paired with one sulfate group, and packed alongside it, six water molecules tag along. Those six waters draw in a surprising amount of scientific attention. Without them, the texture, color, and properties shift. Hydrates matter because water changes the way nickel sulfate performs, dissolves, and reacts.

Growing up, I used to watch a family member fix old electronics down in the basement. The tools were messy, sometimes improvised, but the plating process was always precise. I didn’t know back then, but nickel sulfate hexahydrate played a role in making sure metal surfaces stayed strong and rust-resistant. Plating shops don’t use some theoretical version of this compound. They use the hexahydrate form, for practical reasons. Six water molecules make it easier to measure, handle, and mix. You end up with a reliable result, and people rely on that durability in everything from kitchen utensils to power tools.

Bigger Picture: Batteries and Beyond

Nickel sulfate hexahydrate isn’t just for metal plating. Electric cars and lithium-ion batteries depend on nickel-based compounds for storage and efficiency. According to International Energy Agency data, battery demand is expected to hit record levels by 2030, and nickel sits near the top of the ingredient list. Refiners choose the hexahydrate form because it dissolves more smoothly, and manufacturers find the quality of the finished cathode improves as a result.

There’s no shortage of concern about raw material sourcing. As demand increases, producers face supply chain and environmental pressures. Responsible sourcing and improved recycling can reduce the pressure, but that takes long-term planning. Governments, producers, and researchers can support better recycling tech, so old batteries get reclaimed rather than tossed away. I’ve seen reports in both trade and mainstream media highlighting the risk posed by unethical nickel mining. Tracing ingredients, using digital tracking solutions, has moved from a novelty to a necessity for many battery makers.

Learning and Health

Ignorance about what’s actually inside common materials can be risky. Nickel allergies affect a fair chunk of the population, and accidental exposure causes real pain for those affected. The hydrate version carries the same risks, so safety data and informed handling should remain a core part of any workplace. Wearing gloves and following clear guides helps, but continued education matters just as much. For students, coders, tinkerers, or anyone working with batteries, knowing a formula like NiSO4·6H2O means knowing exactly what you’re using and what precautions make sense.

Smarter Solutions for the Future

Research keeps driving new uses for nickel sulfate hexahydrate. People ask for safer, greener chemistry and smarter recycling. Real progress comes from small steps—a shift to reused materials in plating or encouraging manufacturers to certify their battery supply chains. Trust grows as companies share more about their processes and material origins. Everyone, from students to engineers, benefits when chemistry stays transparent and approachable.

Understanding What’s At Stake

People working in industries like battery manufacturing or electroplating see Nickel Sulfate Hexahydrate up close. This bright green crystal lands in the workplace because modern tech and green energy rely on nickel chemicals every day. Safety officers bring up the topic a lot, especially since more demand for electric vehicles means more exposure on factory floors.

Human Health Risks

Nickel sulfate doesn’t belong in the body. Inhaling dust or letting it touch the skin can trigger allergic reactions for many people. Nickel allergy tops the list of contact allergies worldwide, leading to painful rashes that take weeks to heal. For some, the response goes deeper, causing breathing issues or even asthma. A group of researchers found that workers handling nickel compounds develop higher rates of nasal and lung cancers, especially with chronic contact.

Everyday exposure comes from jobs, but contamination can reach groundwater if someone dumps the waste improperly. Nickel sulfate dissolves easily, so drinking water can carry small amounts. Even at low doses, extended contact can mess with kidneys and the liver. There’s no need to panic about brief, one-off exposure, but in places where regulation falls short or safety gear gets ignored, the risk builds up fast.

Environmental Concerns

Animals and plants react badly to nickel sulfate in the ecosystem. Fish and aquatic life struggle if it washes into rivers or lakes. Excess nickel upsets soil chemistry, making it harder to grow food or maintain natural habitats. The US Environmental Protection Agency lists nickel sulfate as a hazardous substance due to this potential to upset life cycles in the environment.

Regulations and Workplace Control Measures

Rules aren’t just made for red tape. OSHA limits workplace airborne exposure to protect lungs and skin of workers. The European Union classifies nickel sulfate as a carcinogen. Factories set up exhaust hoods, provide gloves, and install air monitors thanks to stories from the past—workers suffered real harm before anyone paid attention. Labeling and safe storage help. Training matters just as much. In a lab or factory, safety glasses and respirators aren’t optional if nickel sulfate is nearby.

Reducing Risks and Moving Forward

Switching to less hazardous substitutes for specific processes sometimes brands as ‘green chemistry.’ Some companies already use closed systems to keep dust out of the air and work benches. Personal experience in a lab confirms this—routine air checks and glove rules dramatically cut sneezing fits and hand rashes, making productivity rise as accidents fall. For waste, treatment facilities can remove nickel before water leaves the plant.

Communities should push for transparency. Workers deserve full info on what they handle, not just in small print but through talks and demonstrations. Doctors need to recognize signs of nickel exposure, especially in regions with lots of battery or plating jobs. More recycling of nickel keeps the supply chain circular, reducing raw demand and spill risk.

Accountability and Knowledge

People rarely worry about chemicals like nickel sulfate until a headline or an accident. It makes sense for everyone—factory bosses, regulators, scientists, neighbors—to stay on alert. The facts are clear: unchecked nickel sulfate brings real hazards. Fast action, steady training, and openness on chemical risks close the gap between industry and safety.

Why Nickel Sulfate Hexahydrate Demands Care

Nickel sulfate hexahydrate looks unremarkable at first. In reality, its green-blue crystals belong in the same family as many strong industrial chemicals—helpful, yet only when given proper respect. Anyone who has worked in plating shops or labs knows this stuff stains, corrodes, and, above all, triggers health concerns if handled poorly. Inhaling the dust or letting it soak through the skin brings real risks, especially with frequent exposure. The science confirms it: exposure runs the risk of allergic skin reactions, respiratory sensitivity, and even possible carcinogenic effects over the long term. Respect becomes the price of safe use.

Understanding Storage Challenges

Moisture turns small problems big. Though this compound comes with six molecules of water clinging to every nickel-sulfate molecule, outside humidity only speeds up its breakdown. Pooled water causes caking, which makes dosing tougher and invites chemical changes that someone working with precise formulations can’t ignore. On top of that, spills on the storage floor corrode metal shelving and fill the air with potentially dangerous dust. Noticing the creeping blue-green stain once already means something got sloppy.

Best Practices from the Field

What works in real facilities rarely matches the textbook ideal. I’ve seen bags tossed carelessly onto floors, but that shortcut delivers headaches down the road. Secure nickel sulfate hexahydrate in plastic or glass containers that actually seal, not those metal bins that corrode in months. The typical high school chemistry stockroom smells faintly of chemical leaks after a season—a clear warning. Tight seals prevent both leaks and contamination from other powders or debris.

Keep storage containers in dry, cool spots, away from direct sunlight or sources of heat. Sun warms those plastic tubs, and the inside humidity spikes. The best places run below 25°C with strong ventilation: dust that escapes will drift far without good airflow, but old, poorly ventilated stockrooms see that dust turn into persistent contaminants. Don’t store near acids, strong oxidizers, or anything flammable. Nickel chemistry sometimes surprises, and surprises here tend to cost money or cause injury.

Labeling and Security

A faded label has ruined more than a few workdays. Fresh, bold labeling prevents confusion, especially on containers reused between shipments. Data such as the contents, hazard marks, and a clear storage date matter if you want to trace problems later. Locked cabinets or controlled-access rooms keep out anyone not trained in safe handling. Walk through any reputable lab, and the nickel chemicals wait behind extra barriers compared to the table salt.

Addressing Long-Term Hazards

Crystals breaking down over years release nickel dust that risks more than a single slip. Routine checks keep leaks and buildup in check. I always bring gloves, a mask, and goggles just for restocking—the cleanup after an avoidable spill costs more than the upfront caution. Training others to recognize the first signs of improper storage, like sticky residue or odd smells, marks out a trustworthy team. Regular reminders in safety meetings reinforce these habits, especially for new hires.

Steps Toward Safer Storage in Your Workplace

Simple changes bring serious results. Use reliable containers. Place them high and dry. Keep records, update labels, and teach vigilant habits. These steps prevent exposure, safeguard health, and ensure that work with nickel sulfate hexahydrate remains routine rather than fraught. Wherever precision, safety, and clean work matter, paying attention to storage wins the day—every time.

Battery Manufacturing Leading the Charge

Electric vehicles get people talking about batteries, but most haven’t considered what goes into building powerful, long-lasting batteries. Nickel sulfate hexahydrate plays a crucial part here. Most lithium-ion batteries made for electric cars use nickel to boost energy density and overall performance. Researchers point out that batteries with higher nickel content make cars drive longer on a single charge.

Automakers like Tesla, General Motors, and Volkswagen count on reliable nickel sources to push electric mobility forward. Once a luxury item, electric vehicles have started to claim a bigger share of new car sales because battery costs keep dropping — and a key component is nickel sulfate hexahydrate. Some forecasts from Benchmark Mineral Intelligence expect the global demand for battery-grade nickel to more than double by the end of the decade.

Electroplating and Corrosion Resistance

Most people don’t notice the coating on coins, tools, or bathroom fixtures, but many of these surfaces rely on nickel plating. Through electroplating, manufacturers protect base metals against wear, moisture, and chemicals by laying down a smooth, thin nickel layer. Nickel sulfate hexahydrate offers a reliable chemical form for these plating solutions.

Factories can plate everything from phone parts to bicycle frames. Nickel not only creates a shiny look, it also extends the life of what people use every day — from taps and faucets to nuts and bolts. Industries focus on improving plating baths to lower waste, and many modern shops use closed-loop water systems and strict ventilation to reduce worker exposure and environmental impact.

Catalysts in Chemical Synthesis

Catalysts don’t always grab headlines outside chemistry circles, but they matter for efficiency and sustainability. Chemical plants use nickel sulfate hexahydrate in catalysts for making fats, oils, and fuels. Some large-scale hydrogenation processes — such as turning vegetable oil into margarine — put nickel right in the middle of the action.

Catalytic applications help industries cut energy costs and shrink their environmental footprint. Engineers keep searching for greener ways to handle these processes, focusing on recycling nickel catalysts instead of throwing them away once spent. That shift lowers the demand for mining nickel and reduces hazardous waste.

Textile Dyeing and Pigments

The textile and dye industries have relied on nickel compounds for generations. Nickel sulfate hexahydrate serves as a mordant, locking dyes into fabrics to keep colors vibrant through washes and sunlight. Some specialty pigment producers use nickel salts to create green and blue shades for ceramics, glass, and artistic paints.

There’s a growing push for safer dyeing practices. Many dye houses work to catch wastewater and switch to less hazardous materials, keeping nickel use limited to cases where performance can’t be matched by other substances.

Looking Toward Responsible Use

After years working near industrial supply chains, I’ve seen the benefits of nickel sulfate hexahydrate firsthand. Jobs created, innovations in transportation and technology, reliable infrastructure — all trace back in some way to nickel chemistry. It’s also clear the risks demand careful management. Nickel compounds, including nickel sulfate hexahydrate, require safe handling and controls to protect workers and surrounding communities.

Safer substitutes and better recycling practices are taking root. Companies and regulators share the responsibility to monitor exposure levels and invest in greener alternatives. The goal remains the same: keep building advanced technologies, but do it without creating new problems for the next generation.

| Names | |

| Preferred IUPAC name | hexaaquanickel(2+) sulfate |

| Other names |

Nickel(II) sulfate hexahydrate

Nickel monosulfate hexahydrate Nickel sulphate hexahydrate |

| Pronunciation | /ˈnɪk.əl ˈsʌl.feɪt ˌhɛk.səˈhaɪ.dreɪt/ |

| Identifiers | |

| CAS Number | 10101-97-0 |

| Beilstein Reference | Beilstein Reference: 3595582 |

| ChEBI | CHEBI:61361 |

| ChEMBL | CHEMBL1239841 |

| ChemSpider | 21515 |

| DrugBank | DB14537 |

| ECHA InfoCard | 03d5d19b-cb38-41d0-827d-18db7e3d6ded |

| EC Number | 232-104-9 |

| Gmelin Reference | 78078 |

| KEGG | C13951 |

| MeSH | D009547 |

| PubChem CID | 24856 |

| RTECS number | QR9600000 |

| UNII | 23N9G6U88Z |

| UN number | UN3077 |

| CompTox Dashboard (EPA) | DTXSID7032945 |

| Properties | |

| Chemical formula | NiSO4·6H2O |

| Molar mass | 262.85 g/mol |

| Appearance | Blue or green crystalline solid |

| Odor | Odorless |

| Density | 2.07 g/cm³ |

| Solubility in water | 816 g/L (25 °C) |

| log P | -4.5 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 6.0 |

| Basicity (pKb) | 8.55 |

| Magnetic susceptibility (χ) | Paramagnetic |

| Refractive index (nD) | 1.484 |

| Dipole moment | 6.482 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 279.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1976.6 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V07AY30 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and eye irritation, may cause an allergic skin reaction, may cause cancer, suspected of damaging fertility or the unborn child, toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS07, GHS08, GHS09 |

| Pictograms | GHS05,GHS07,GHS09 |

| Signal word | Danger |

| Hazard statements | H302, H315, H317, H319, H334, H341, H350i, H360D, H372, H410 |

| Precautionary statements | P210, P273, P280, P302+P352, P305+P351+P338, P308+P313, P501 |

| Lethal dose or concentration | LD50 Oral Rat 264 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 264 mg/kg |

| NIOSH | WX2080000 |

| PEL (Permissible) | PEL (Permissible): 1 mg/m3 (as Ni) |

| REL (Recommended) | 0.1 mg Ni/m³ |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Nickel(II) sulfate

Nickel(II) chloride Nickel(II) nitrate Nickel(II) acetate Cobalt(II) sulfate Copper(II) sulfate Iron(II) sulfate |