Nickel Acetate Tetrahydrate: A Closer Look at an Unsung Industrial Player

Historical Development

Progress in nickel chemistry surged during the second half of the nineteenth century, but workers in galvanoplasty, dyeing, and ceramics reached for nickel acetate even earlier as they tinkered with new colorants and plating formulas. By the early 1900s, scientists realized that nickel acetate tetrahydrate’s unique solubility, compared to nickel sulfate or chloride, unlocked new ways of making clean, consistent nickel deposits in aqueous systems. Industrial adoption grew in step with demand for better metal finishes. Each decade that followed brought tweaks to crystal handling, purity measurement, and large-scale production, as high-purity nickel became essential to everything from coinage to electronics. I’ve seen how these incremental steps built a backbone for key modern technologies—often in places we take for granted, such as the fine traces on a printed circuit board or the reflective layer on data disks.

Product Overview

Nickel acetate tetrahydrate appears as green, slightly efflorescent crystals, easy to distinguish on the bench from other nickel compounds. Major suppliers ship it with a typical nickel content near 22% and acetic acid at about 31%, but these numbers fluctuate with humidity control and storage practices. The material finds its way into laboratories worldwide and into manufacturing lines where metal surface treatments or electrolytic baths help shape the durability and appearance of finished goods. Manufacturers focus on consistent hydration, a task that requires attention, especially when the end use demands a narrow range of impurity metals or acidic residues. Workers in surface engineering, especially those who grew up in the age of point-and-click ordering, sometimes overlook just how much precision matters in sourcing the base material.

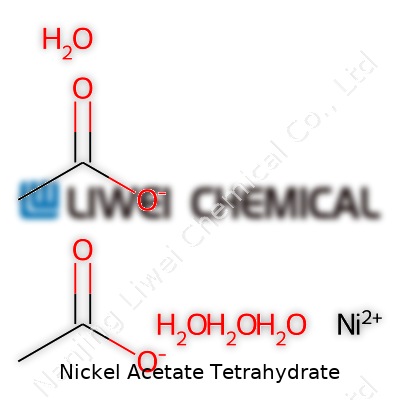

Physical & Chemical Properties

Anyone who has handled nickel acetate tetrahydrate recognizes its cool, crystalline texture and striking blue-green hue. The compound carries a molecular formula of Ni(CH3COO)2·4H2O and a molar mass around 248.84 g/mol. Its water solubility and mild vinegar odor betray its acetate roots, and its tendency to decompose around 300°C remains a reminder to store and heat it with care. In my experience, the main practical challenges spring from its sensitivity to air and moisture, which can lead to clumping or partial loss of water of crystallization—a headache for analysts chasing reliable stoichiometry or any process demanding tight controls.

Technical Specifications & Labeling

Industrial and laboratory specifications call for strict limits on iron, cobalt, copper, and zinc—usually less than 10 ppm for high-purity grades. Labeling often emphasizes the hydration level, since that affects not only calculations but also the way the product behaves in reactors and plating baths. Packagers apply color-coded caps, batch numbers, and shelf-life recommendations. Labels reflect both regulatory pressures and real-world user needs for traceability. Even after years sorting through shelves, I find that product mislabeling still causes more headaches than actual contamination in day-to-day lab work.

Preparation Method

Most processes rely on dissolving nickel carbonate or nickel hydroxide in glacial acetic acid, or treating nickel metal with acetic acid under controlled conditions to minimize air oxidation and unwanted nickel oxide byproducts. The resulting solution is allowed to cool and crystallize, then the crystals are filtered, rinsed, and dried at low temperatures to retain hydration. Scale-up brings a slew of new variables—vessel cleanliness, mixing rates, cooling gradients—all of which tweak the crystal habit and, ultimately, the product’s handling. Over the years, I’ve watched teams finetune these operating variables in a constant push for scale and cost savings.

Chemical Reactions & Modifications

Nickel acetate tetrahydrate dissolves easily in water, alcohols, and mixes well with other metal acetates. Heating triggers it to lose water molecules, stepwise, up to the anhydrous form, which itself decomposes further back to nickel oxide and acetic acid vapors at higher temperatures. In electroplating, it serves as a reliable nickel ion source. Chemists use it to synthesize mixed-metal catalysts, battery precursors, and functional materials by precipitation or coprecipitation with other salts. Sometimes, small changes in reaction temperature or PH change everything about the resulting precipitate’s morphology or catalytic properties, which makes nickel acetate tetrahydrate a tool with both predictable and surprising outcomes.

Synonyms & Product Names

This compound hides behind several aliases in catalogs and technical papers: nickel(II) acetate tetrahydrate, nickel diacetate tetrahydrate, and even “acetic acid, nickel(2+) salt, tetrahydrate.” In trade, some suppliers use internal codes or abbreviations, but in my experience, most end-users stick with plain “nickel acetate” or “nickel acetate tetrahydrate.”

Safety & Operational Standards

Nickel compounds draw strict oversight because of their toxicity and allergenicity. Nickel acetate tetrahydrate, while less aggressive than nickel carbonyl or powdered nickel, still poses risks through inhalation, skin contact, and accidental ingestion. Operations must run with gloves, goggles, and fume hoods. Long-term exposures can sensitize workers or cause skin problems. Emergency showers and eyewash stations aren’t just for show—they’ve saved coworkers from real harm more than once. Every drum and flask must carry right-to-know labels. Facilities track waste disposal under hazardous codes, and local authorities often drop in for surprise audits. Navigating this web can be daunting for new staff, but no seasoned operator cuts corners with nickel.

Application Area

Nickel acetate tetrahydrate found its place in surface finishing first, especially as a sealing agent for anodized aluminum, where it reacts to form a nickel-rich surface layer that repels corrosion. Plating bath chemists choose it to tweak deposit characteristics or prepare intermediate nickel layers that boost final adhesion. Artists and electroformers prize it for colored finishes and controlled deposit build-up. Beyond plating, it has roles in cathode material synthesis for rechargeable batteries, and as a precursor for catalysts used to accelerate hydrogenation or organic transformations in industrial reactors. Textile workers sometimes encountered it in dye mordanting, although tighter safety rules have trimmed its appearance there. Each of these uses brings unique technical demands, but in my experience, problems most often arise from process contamination or hydration management, not from the chemistry itself.

Research & Development

Researchers keep finding new ways to coax performance out of nickel acetate tetrahydrate. Materials scientists explore it as a precursor for layered oxides and hydroxides for use in batteries and fuel cells—a sector that rides the boom in energy storage. Teams studying nanomaterials rely on it to seed metal-organic frameworks that step up gas adsorption or catalysis. A glance through the literature shows a steady stream of new preparative routes and dopant strategies. I've watched graduate students push catalog reagents like nickel acetate to make tiny improvements in electrode life or sensor selectivity, with real-world payoffs showing up years down the line.

Toxicity Research

Studies of nickel toxicity stretch back more than a hundred years. Today, there’s no doubt that nickel acetate tetrahydrate carries risks: inhalation can cause respiratory problems, long-term exposure raises cancer risk, and many people develop skin sensitization. Animal studies help set occupational limits, and safety data sheets spell out handling precautions in plain language. Some modern work looks beyond acute symptoms, measuring nickel’s subtle effects on DNA or organ function. Research into alternatives or safer forms of nickel points toward a future where risk goes down, but every lab worker and plant operator owns responsibility for careful use—avoiding shortcuts, double checking ventilation, and refusing to accept outdated safety practices.

Future Prospects

Nickel acetate tetrahydrate stands to become even more important as technology continues to demand efficient, scalable nickel sources. As battery manufacturers scale new chemistries for electric vehicles and renewable energy storage, high-purity nickel salts will see more demand. Environmental regulations push manufacturers to design safer processes and cut waste. Researchers continue to probe for nickel acetate’s limits, exploring it in thin films, advanced ceramics, and targeted drug delivery. From my own vantage in both academic and industrial settings, future prospects shine brightest where teams learn from the material’s checkered history in safety and handling, and build on that with smart synthesis and creative application.

Nickel Plating: Adding More Than Just Shine

Nickel acetate tetrahydrate doesn’t show up in everyday conversation, but flip over a handful of coins or check the wear on your house keys—chances are, nickel is keeping them shiny and corrosion-free. This water-loving chemical turns up often in the final rinse bath in nickel electroplating. During my stint in a local repair shop, I watched old tools get their edge and gleam back thanks to a layer of nickel. The secret to that smooth, even finish often comes down to how well the rinse seals in the nickel coating, protecting the metal beneath from rust. Real stakes ride on it in auto parts and electronics, too. In both cases, nickel acetate acts like glue between the raw metal and the outside world.

Color Fixing in Dyes and Textiles

Textiles rely on chemistry for color as much as artistry. In textile factories, nickel acetate serves as a mordant—a chemical assistant that helps dyes lock to textiles. Imagine dropping a wool sweater in the wash, praying your favorite shade won't bleed. This compound steps up to bind the dye to the material, making colors last through wear, light, and heat. Dye houses depend on nickel acetate to keep those vibrant reds and deep blues from fading too fast, turning simple cloth into something lasting.

Catalysis: Fueling Reactions Behind the Scenes

Catalysts don’t often get credit, but they drive reactions that make modern industry tick. Nickel acetate tetrahydrate steps into this world by helping convert raw chemicals into valuable products, from specialty plastics to medical compounds. I once toured a small-batch chemical plant where staff relied on nickel-based catalysts to hurry along vital reactions—speeding up production, cutting down waste, and saving energy in the process. Its reliability keeps costs down and supply chains moving in everything from drug manufacturing to green energy research.

Laboratory Experiments and Research

In college labs, nickel acetate showed up in experiments chasing new battery designs and nanotechnology. The reason? Its predictability and solubility helped students and researchers control the metal content precisely, test reactions cleanly, and tweak formulas until something new clicked into place. This hands-on work trained young scientists and offered glimpses of new products, from better solar panels to more durable electronics, that might hit the market one day.

Concerns Over Safety and Environmental Impact

Despite its uses, nickel acetate tetrahydrate deserves caution. Inside factories, workers guard against inhaling powders or letting solutions linger on the skin. Too much exposure to nickel compounds raises real health risks, including rashes and, in the worst cases, links to cancer. Labs and workshops use sealed systems and strict rules to keep spills and dust to a minimum. Wastewater from nickel-based processes gets treated before it leaves a facility—a response to growing concern about heavy metals in soil and water. Going forward, industry may lean on new purification tech or greener alternatives to cut down on nickel waste, balancing innovation with responsibility.

Looking for a Better Balance

Nickel acetate tetrahydrate keeps the world’s gears turning, but it also serves as a reminder to treat chemistry with respect. Its value runs deep, helping create brighter clothes, stronger gadgets, and better batteries. Yet, the drive for innovation needs to match up with a willingness to handle risks and find safer solutions wherever possible. This balance matters, not just for companies, but for everyone relying on products that last without leaving a stain on the world around us.

Looking at a Common Lab Compound

Nickel acetate tetrahydrate shows up often in chemistry labs, especially in classes and industries working with plating and catalyst preparation. The chemical formula is Ni(CH3COO)2·4H2O. This formula tells a lot about its structure: one nickel ion hooked up with two acetate groups, soaked with four water molecules. It might sound like dry chemistry, but understanding this formula lays the groundwork for safe handling and smart use.

A Closer Look at Why the Formula Matters

Handling chemicals like nickel acetate demands more than just knowing a name. The precise formula lets users make correct calculations. Accuracy matters, especially in rare situations like plating coins or making specialized catalysts. I remember a project where mistaking anhydrous for hydrated nickel acetate threw off our calculations, led us to buy extra materials, and wasted both time and money. Lessons like that stick, especially when working with something that stains hands green and leaves a metallic tang in the air.

Why Water of Hydration Is Not Just a Detail

Four water molecules might seem like an afterthought to a beginner, but anyone who’s mixed chemicals on a hot plate knows these molecules impact mass, solubility, and how the chemical behaves. Skip the detail and you might end up with unpredictable results. In industries where process control is non-negotiable, misunderstanding what "tetrahydrate" means causes wasted batches or, worse, serious safety hazards.

Importance in Getting the Details Right

The chemical world plays tough. Nickel acetate tetrahydrate illustrates this. The formula doesn’t just live on paper. It ties directly to how much substance goes into an electroplating bath, or what ends up in waste streams. A single error creates downtime or puts the workplace at risk. Quality control teams check incoming shipments of nickel acetate for exactly this reason. Lab technicians use the formula to write safety data sheets. Teachers drill students on it, knowing that one misunderstanding can lead to real-world mistakes.

Health and Safety Connections

Nickel compounds don’t give second chances with health. The formula points toward how to store, label, and dispose of the compound. Breathing in dust from nickel acetate can trigger asthma or skin reactions. That’s not just theory — keeping gloves on and minimizing exposure has saved many chemists from finding out the hard way just how reactive nickel salts can be. The "tetrahydrate" part means storing the chemical away from heat, so it doesn’t lose water and change properties.

Stepping Toward Practical Solutions

Building a safety culture and ensuring clean processes often starts with knowing the chemical formula by heart. Quick training sessions, clear container labels, and accessible reference charts make a difference. There’s no magic in these routines — just the steady habit of double-checking work and encouraging open sharing if someone’s not sure about a formula. Mistakes get caught before they matter, especially for hazardous materials like nickel acetate tetrahydrate.

Learning the Value Beyond the Label

Using this understanding, chemistry students and professionals shape habits that carry into careers. Whether it’s making better batteries, working on art conservation, or recycling metals, knowing the formula for nickel acetate tetrahydrate turns into a tool for safer work, solid teamwork, and better results.

Understanding the Risks

Nickel acetate tetrahydrate looks harmless at first glance. Green crystals, often tucked away in a classroom or a corner shelf at a lab—it’s easy to forget this stuff is more than just a compound. I’ve handled it during plating projects. A quick slip-up, and you realize just how serious chemicals like this can be. Inhaling dust irritates the lungs. Touching it too much causes skin sensitivity. A bag left open? Moisture from the air creeps in—before you know it, the chemical’s structure changes, and that affects both your results and your safety.

Proper Containers Make All the Difference

A lot of schools and small shops use whatever container’s on hand: plastic food containers, brown glass jars, sometimes even old coffee cans. That’s a recipe for mistakes. Chemicals don’t wait politely for attention—they react to the environment. Storing nickel acetate tetrahydrate works best in tightly sealed containers made of materials that won’t react with acids or bases. Polyethylene or polypropylene screw-cap bottles do the job. Glass works as long as it’s kept dry and the lid fits tight. Label every bottle—big, clear writing, date of purchase, and hazard notes right on the front. Never trust your memory on this.

Temperature and Location Matter

I’ve seen folks stash jars on the nearest shelf—right under sunlight or above a radiator. Not smart. Nickel acetate tetrahydrate breaks down with heat and moisture. Store it in a cool, dry spot, away from windows, heaters, or sinks. Locking cabinets are best, especially if you share space with kids or pets. An open shelf at eye level keeps the risk of spillage low. Aim for a spot where temperatures stay below 25°C and humidity’s consistently low. Too much warmth, and the water molecules leave the crystal, changing its effectiveness and safety profile.

Keep It Away From Food, Drink, and Flammables

Mistakes happen when lab supplies and household items get mixed up. Nickel acetate tetrahydrate should never share space with anything edible. Nickel compounds pose serious health hazards if they sneak into food prep areas. Keep it out of kitchens and break rooms—store it in a dedicated chemical area. You also want to avoid putting it near flammable solvents or strong acids. If you’ve got a space for oxidizers or fuels, store this compound elsewhere. If a fire breaks out, incompatible chemicals only make things worse.

Access Control and Regulation Compliance

Chemicals don’t belong in reach of everyone. Only trained folks should handle nickel acetate tetrahydrate. In my first job, a new staff member mixed up two similar jars, and we had to throw out both batches—too risky to guess which was which. Safety data sheets need to stay nearby, and every user should read them before touching the chemical. Regulations aren’t just red tape. OSHA and the EPA set storage standards for a reason: to ensure safety and minimize environmental harm. Follow the rules, keep records, and check expiry dates.

Handling Spills and Waste

Spills can happen even in careful hands. Keep absorbent materials and a dustpan nearby. Wear gloves and a dust mask every time—skin reactions sneak up fast. Store waste in a separate, clearly marked container, and never pour leftovers down the drain. Disposal takes planning—look up your local hazardous waste program, and follow their instructions to the letter.

Conclusion: Mindful Habits Prevent Trouble

Treat nickel acetate tetrahydrate with respect. Use proper containers, keep it cool and dry, separate it from food and anything flammable, and give access only to those who understand what they’re doing. Safe storage is the most important step in keeping experiments productive—and people healthy.

Why Nickel Acetate Calls for Respect

Anyone who has worked in a lab or shop knows some chemicals pack a punch if mishandled. Nickel acetate tetrahydrate looks almost harmless—blue-green crystals, not too scary on the shelf. Still, it pulls no punches if it gets on your skin, in your eyes, or, worst of all, in your lungs. Nickel itself rates as a human carcinogen. That fact alone sharpens the need for good habits every step of the way, even if you only work with it occasionally. I learned this straight away as a young tech, back when cutting corners seemed clever. One rash or cough later, I ended up respecting the protocols that old-timers had hammered home.

Personal Protection: A Non-Negotiable

At the most basic level, gloves made from nitrile or neoprene keep the stuff off your hands. Cotton doesn’t cut it; nickel acetate sneaks right through. Proper gloves, not those dollar-store deals, give you a reliable barrier. Any splash will mess up your skin fast—itching, rashes, and potentially worse reactions after repeated exposure. Safety goggles do just as much work. I’ve seen people lose a few days of their lives to eye flushes because they thought their glasses counted as protection. Tightly fitting goggles make chemical splashes far less likely to ruin your day.

Lab coats or coveralls come next. Don’t bring home anything you wouldn’t want touching your family. Changing out of your work clothes at the end of a shift prevents the nasty surprise of nickel dust on your car seats or living room couch. Good shoes, closed-toe, with the right material, seal the deal for personal protection.

Keep Dust and Fumes Far Away

Nickel acetate, breathed in, does far more damage than on the skin. People who’ve worked with it for years say that one slip, one gust in the wrong direction, can turn a routine morning into a hospital visit. Work in a fume hood or use solid local exhaust ventilation. Don’t use it in an area with a ceiling fan and call it “airflow.” Properly ducted ventilation clears those invisible particles before your lungs get a chance. If you handle larger quantities, think about a fit-tested respirator. Mask store shelves flood with cheap knock-offs, but only NIOSH-certified gear stands up to the task.

Housekeeping and Hygiene

You can’t cut corners with clean-up. Surfaces, tools, and even personal belongings need a wipe-down with a dedicated chemical cleaner, never just water. Water alone leaves a film, which means your next cup of coffee could pick up traces of nickel if you’re not careful.

Wash hands and forearms with soap before eating, drinking, or stepping out. I once watched someone skip this after handling the compound, only to end up with a mouthful by way of a sandwich. That lesson stuck with everyone who saw it.

Storage and Emergency Planning

Don’t leave nickel acetate anywhere it could get mistaken for something else, especially food or drink. Secure it in a sturdy, clearly labeled container far from heat and direct sunlight. Spill kits, eyewash fountains, and emergency showers all stay ready nearby. Practicing their use means you don’t fumble when time matters most.

Better Solutions: Substitution and Training

If possible, switch to safer alternatives. Newer compounds sometimes provide similar benefits without the risks that nickel brings. Companies with tight safety budgets often overlook this, yet long-term health costs far outweigh short-term savings. Regular training and visible warning signs help keep these dangers front of mind, especially for new hires or guests in the workspace. I saw entire teams dodge disaster because one person remembered a drill.

Pursuing Reliable Chemistry

Walk into any lab or plating shop, and you’ll find people eyeing labels and certificates with a mix of trust and suspicion. Purity isn’t a small detail with nickel acetate tetrahydrate. The product grade steers the results, determines waste, and often drives cost. Many will ask, “What is the purity of your nickel acetate tetrahydrate?” before they even talk pricing. If you’re on the buying side, nothing less than specifics will do.

Why Purity Drives Everything

Platers, researchers, and pharmaceuticals work hard to avoid surprises. Impurities hitchhike on every reaction, so high purity—often reaching 98% or more for analytical grade—is the baseline for predictable science. I’ve tried workarounds with lower grades just to save a few bucks; instead, costly do-overs always followed. Even the presence of less than 1% unwanted elements—chlorides, sulphates, iron, or copper—messes with bath chemistry or contaminates a reaction. The impacts stretch further than an off-color finish or a botched data set.

Most suppliers aim for 98-99% pure nickel acetate tetrahydrate, with trace elements measured down to parts per million or less. Analytical and reagent grades take this standard even higher. I’ve seen data sheets from reputable suppliers showing iron and copper below 0.001%. That level of detail keeps the wheels turning in industries where failure can’t be shrugged off. Try running a nickel electroplating bath with a contaminated salt—problems pile up fast, with expensive rework on every item on the rack.

Facts Over Guesswork

Purity isn’t guesswork. Suppliers with a care for quality run each batch against certificates of analysis. Visual inspection doesn’t cut it—real trust comes from independent test results (ICP, AAS or gravimetric analysis). I once received a barrel with a “high purity” label, only to discover iron running off-scale. By that point, product runs were in progress. That batch wiped out a week of labor. No paper trail, no reliable data—no thanks.

This is where E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) becomes tangible. Vendors open about their testing process and source channel inspire confidence. Experience in the field helps interpret what those tiny contaminant numbers mean for end results. Authoritative producers aren’t shy with data, sharing full COAs and regularly audited processes.

Buying Decisions That Make Sense

Anyone buying nickel acetate tetrahydrate should start with a clear picture of what’s at stake. Ask for the full analytical certificate. Dig for trace element data—iron, copper, and even sodium and zinc. Cross-reference those results with your industry threshold. I’ve switched suppliers mid-stream if a COA didn’t match internal specs. Even if a product claims “lab grade”, the only measure that counts is the actual impurity profile.

It works both ways. If something’s off after a plating run or a chemical reaction falls flat, head back to those purity numbers. If the label offers vague promises and no third-party testing, that’s not a gamble worth taking. In today’s world—with so much riding on product consistency—the demand for clear, honest reporting is justified. Trust the facts, not the fluff.

| Names | |

| Preferred IUPAC name | Nickel(II) acetate tetrahydrate |

| Other names |

Nickel(II) acetate tetrahydrate

Nickel diacetate tetrahydrate Acetic acid, nickel(2+) salt, tetrahydrate |

| Pronunciation | /ˈnɪk.əl ˈæs.ɪ.teɪt ˌtɛt.rəˈhaɪ.dreɪt/ |

| Identifiers | |

| CAS Number | 6018-89-9 |

| Beilstein Reference | 4158737 |

| ChEBI | CHEBI:62984 |

| ChEMBL | CHEMBL3306607 |

| ChemSpider | 21447 |

| DrugBank | DB14511 |

| ECHA InfoCard | ECHA InfoCard: 100.028.290 |

| EC Number | 209-169-8 |

| Gmelin Reference | 81678 |

| KEGG | C18957 |

| MeSH | D009538 |

| PubChem CID | 160898 |

| RTECS number | QR6125000 |

| UNII | C91WRL1XP7 |

| UN number | UN3077 |

| CompTox Dashboard (EPA) | DTXSID2044371 |

| Properties | |

| Chemical formula | Ni(CH3COO)2·4H2O |

| Molar mass | 248.86 g/mol |

| Appearance | Green crystalline solid |

| Odor | Odorless |

| Density | 1.744 g/cm³ |

| Solubility in water | Moderately soluble |

| log P | -1.4 |

| Acidity (pKa) | 4.76 |

| Basicity (pKb) | 7.82 |

| Magnetic susceptibility (χ) | +2190e-6 cm^3/mol |

| Refractive index (nD) | 1.500 |

| Viscosity | Viscous liquid |

| Dipole moment | 2.09 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 254.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1732.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2065 kJ/mol |

| Pharmacology | |

| ATC code | V07AY |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin irritation, causes serious eye irritation, may cause an allergic skin reaction, may cause cancer, may cause damage to organs through prolonged or repeated exposure, toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H317, H334, H341, H350i, H372, H412 |

| Precautionary statements | Precautionary statements: P261, P264, P272, P273, P280, P302+P352, P304+P340, P305+P351+P338, P308+P313, P314, P321, P332+P313, P333+P313, P337+P313, P362+P364, P391, P501 |

| Lethal dose or concentration | LD50 oral rat 350 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 350 mg/kg |

| NIOSH | QR3500000 |

| PEL (Permissible) | PEL (Permissible): 1 mg/m3 (as Ni) |

| REL (Recommended) | 0.015 mg(Ni)/m³ |

| IDLH (Immediate danger) | IDLH: Not established |

| Related compounds | |

| Related compounds |

Nickel(II) chloride

Nickel(II) sulfate Nickel(II) nitrate Cobalt(II) acetate Copper(II) acetate |