Copper Pyrophosphate: A Grounded Look at Its Journey, Uses, and Safeguards

Tracing the Roots: Historical Development

For more than a century, copper compounds have played a silent role in the backdrop of industrial evolution. Copper pyrophosphate, with its chemical formula Cu2P2O7, started showing up in the records around the early 1900s, thanks to demands in metal plating. Earlier, folks relied heavily on simple copper salts like copper sulfate for electroplating, but uneven finishes and poor adhesion prompted researchers like Watts and Blum to seek alternatives. They discovered that moving toward a pyrophosphate bath meant cleaner deposits, longer bath life, and fewer health complaints from workers. Electroplating shops across Europe and North America soon recognized these improvements, gradually shifting to systems based on this finely-tuned compound.

Product Overview

Copper pyrophosphate stands out as a dark green or a bluish powder, often sold for technical applications. It mainly serves in non-cyanide electroplating solutions—a conscious switch from more hazardous, cyanide-based formulas. Laboratories and factories don’t just see it as a commodity; it's a trusted component, relied on for throwing power and corrosion resistance. Packaging takes care to preserve its moisture content and reactivity, and suppliers provide thorough paperwork to meet industrial traceability standards.

Physical and Chemical Properties

The substance features a molecular weight of around 285.57 grams per mole. It barely dissolves in water, which might seem like a nuisance, but this limited solubility turns into an advantage during plating by minimizing unwanted reactivity and side reactions. Melt it up past 1,100°C and it breaks down, showing its stability at ambient and working temperatures. The olive-green color gives a clue to anyone handling bulk quantities—a helpful sign in the chaos of materials storage. As a phosphate salt, it resists breakdown in neutral or mildly alkaline conditions, avoiding the pitfalls of copper salts that quickly change form or spill toxic ions under stress.

Technical Specifications & Labeling

Producers define strict limits for purity, calling for a copper content hovering near 37.0%. Most companies monitor for iron, lead, and chloride down to parts per million. Moisture content sits below 2%, as water can clump the product and trigger premature reactions. Labels typically state the compound name, CAS number (10102-90-6), net weight, batch code, shelf life, and manufacturer info for full traceability. Safety data sheets include handling instructions under local hazardous material guidelines. Technical data packs help facility engineers compare grades and fit them with established bath recipes.

Preparation Method

Manufacturing starts by blending copper(II) sulfate with disodium phosphate under controlled heat and pH. The copper and phosphate ions join forces, creating a precipitate that’s filtered and washed repeatedly to chase off sulfates and excess sodium. Careful drying under vacuum or gentle heat yields the characteristic fine powder. Larger-scale producers employ closed-loop reactors to minimize waste water and recover valuable byproducts. Quality checks after each stage test the product’s particle size, color, and purity to match demanding end-user requirements.

Chemical Reactions & Modifications

Beyond its baseline use, copper pyrophosphate interacts with various acids and alkalis, breaking apart under acidic conditions and reforming into copper(II) ions plus pyrophosphate. Add strong heat or certain reducing agents, and it converts into copper phosphide or metallic copper—big news for research labs tweaking electrodepositions for batteries or nano-catalysts. Some manufacturers tweak the formula, introducing zinc or other metals to stabilize the crystal structure or match specific plating bath needs. These modifications demand high-level analytical testing, such as X-ray diffraction and trace metal analysis, to guarantee behavior doesn’t swing too far from base standards.

Synonyms & Product Names

In the wider marketplace, copper pyrophosphate crops up under several names: cupric pyrophosphate, copper(II) pyrophosphate, and its older moniker, dicopper pyrophosphate. Suppliers like Sigma-Aldrich, Alfa Aesar, and local niche providers each slap their product codes and batch numbers on shipments, but the chemistry stays the same. Electroplating firms or researchers may use trade names focused on marketing, yet seasoned hands almost always check the chemical index before placing their orders.

Safety & Operational Standards

Copper pyrophosphate brings some health risks, especially during bulk storage, transfer, or mixing into plating solutions. Breathing in dust can cause irritation, and prolonged skin contact may lead to minor rashes. Repeated heavy exposure raises concerns about copper overload in workers, such as headaches, digestive upset, or in severe cases, copper toxicity. Workplaces must offer NIOSH or EU-compliant respiratory protection, eye washing stations, and thorough PPE protocols, tying directly to OSHA and REACH regulations. Spillage management calls for vacuuming powders into sealed bags, never sweeping—a lesson learned after a few nasty cleanups in tight corners. Regular training sessions and incident reviews, along with clear chemical storage signage, cut down on workplace accidents and support long-term employee wellness.

Application Area

Electroplating forms the core market, with printed circuit board factories consuming drums every month to plate intricate copper tracks without the hazards of cyanide. Decorative chrome platers, brass finishers, and even art restoration teams turn to copper pyrophosphate for touch-ups and corrosion protection. Research and teaching labs use it for standardized experiments in electrodeposition, taking advantage of its predictable behavior to educate future chemists and material scientists. Energy storage technology relies more and more on high-purity copper deposits, fueling interest from battery developers and flexible electronics engineers searching for cost-effective, reliable inputs.

Research & Development

New projects in university tech labs and private-sector R&D look to copper pyrophosphate for its tuneable properties. Battery makers want copper coatings with minimal flaws, pushing research into nano-structured bath additives. Medical device engineers explore it as a base for antimicrobial surfaces, thanks to copper’s ability to disrupt bacterial membranes. Environmental chemists have started testing its behavior in water filtration media, searching for efficient heavy metal removal. As industries press for more sustainable and non-toxic solutions, researchers circle back to copper pyrophosphate, noting its history of safe use and adaptability under changing regulatory pressures.

Toxicity Research

Evaluating copper pyrophosphate toxicity goes beyond quick hazard charts. Animal models and cell studies reveal that, though it’s less acutely toxic than copper sulfate, long-term buildup can still stress kidneys, liver, and nervous tissue. Environmental agencies regulate its discharge to shield aquatic ecosystems from copper overload, as too much can disrupt fish development and invertebrate populations. Industrial hygiene surveys regularly measure worker copper levels through blood tests, keeping exposures well under ACGIH limits. Some early evidence links chronic over-exposure to neurodegenerative effects, sparking ongoing investigations into low-dose, long-term risks for both factory teams and downstream communities.

Future Prospects

Copper pyrophosphate holds promise in next-generation electronics, greener plating systems, and new categories in catalysis. Researchers aim for more energy-efficient deposition techniques, tighter recycling of process wastes, and blends with organic additives for bespoke applications. Shifts toward sustainable manufacturing—like closed-loop water treatment and waste copper reclamation—push innovation on both chemical recovery and worker protection. Regulations increasingly shape its use, rewarding producers who minimize impurities and cut toxicity risks. Markets for EV batteries and flexible circuits look for robust, scalable inputs, ensuring copper pyrophosphate’s place in both the legacy industries and the future of high-tech production.

Copper Plating Gets a Spark from Chemistry

Copper pyrophosphate deserves more attention than it gets. For anyone who has watched electronics being built or metal surfaces prepared for new layers, its value becomes pretty clear. This chemical, often found as a blue-green powder, steps up where shiny, pure copper coatings are needed. Think of printed circuit boards inside computers, phones, and medical devices. These boards depend on thin, reliable layers of copper. The old methods, using basic copper sulfate solutions, don’t always hold up when builders want fine details or cleaner surfaces.

Switch to copper pyrophosphate solutions for plating, and the story changes. Factories get smoother copper deposits, fewer burnt edges, and better control over thickness. It’s not just about looks. Surface quality can make or break how a piece handles electricity, heat, or long-term wear. Years ago, I visited a workshop where faulty plating meant expensive do-overs. They’d switched to this chemical mix because it produced better results and let them recycle solution longer, cutting costs and chemical waste. This eco-friendlier edge meant less heavy metal discharge in wastewater.

Electronics Rely on the Right Copper

The need for reliable circuit boards keeps rising. Everything we power up each day runs calculations, sensors, and connections through fine copper lines you can barely see. Getting those lines right goes deeper than just spraying on metal. Copper pyrophosphate baths let companies keep a steady stream of high-quality wiring rolling off the lines without rough spots that could spell short circuits or overheating later.

In one study from the Journal of Applied Electrochemistry, researchers compared several copper plating agents. Copper pyrophosphate stood out for delivering dense, uniform deposits, even where detail mattered. It also plays well with additives that fine-tune the final surface, cutting down on defects or breaks. That means fewer wasted boards, more reliable gadgets, and less stress for everyone down the supply chain.

Beyond Simple Coatings: Specialty Uses

This chemistry isn’t just for mass-produced electronics. Jewelers and artists put it to work, too. They count on controlled plating for intricate designs in costume jewelry or sculptures. For these projects, finish and grain matter as much as function. Electroforming workshops often keep copper pyrophosphate solutions on the shelf for tricky or creative shapes.

At the industrial scale, its use helps tackle tough non-metal surfaces—materials that can’t handle harsh chemicals or high heat. Copper pyrophosphate offers a gentler way to deposit copper onto plastics or glass, opening up new options for odd-shaped electrical connectors or specialty optics.

Steps Toward Cleaner, Safer Processes

There’s no dodging the pollution linked to metal finishing. Still, copper pyrophosphate lets plants cut down on toxic byproducts compared to old-school cyanide-based formulas. In my time consulting for a local plating operation, environmental inspectors favored shops that leaned on these newer chemistries. Regulations now push for safer worker conditions, cleaner drain water, and recycling efforts, making copper pyrophosphate a smarter fit for today’s world.

Room for Improvement and Next Steps

Supply chain hiccups, worker training, and waste management still challenge the plating industry. Investing in on-site labs, operator education, and updated filtration means less chemical exposure and better copper recovery. As electronic gadgets get even smaller and more complicated, expect more labs to invest in copper pyrophosphate and its cousins. It’s not a cure-all, but it gives manufacturers more control, fewer rejections, and a cleaner environmental footprint.

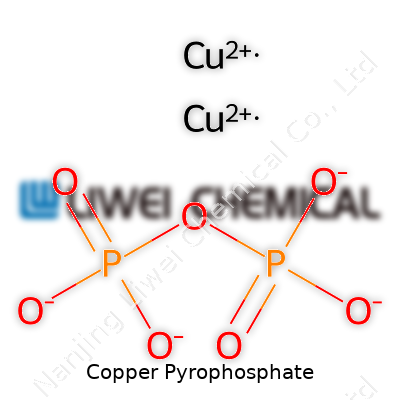

Chemical Formula: Cu2P2O7

Copper pyrophosphate stands out in the toolbox of anyone who’s spent time with electroplating baths. Seeing its chemical formula written as Cu2P2O7 might feel like looking at a secret code to outsiders, but for students, lab techs, or folks in manufacturing, this formula carries real weight. It’s not just a set of random letters and numbers. Breaking it down means actually seeing two copper (Cu) atoms paired up with two phosphorus (P) atoms and seven oxygen (O) atoms.

What the Formula Means in Everyday Use

In most shops where copper finishing takes place, copper pyrophosphate solutions show up regularly. The compound itself brings a unique balance to the plating process—one that you can’t get out of simple copper sulfate baths. Using this formula helps turn out surfaces that look consistent and feel durable. It actually matters to know what you’re handling. The extra oxygen sitting in the pyrophosphate portion helps offer stability and influences deposition quality.

Manufacturing teams sometimes overlook the specifics of the chemicals in play, but that can backfire once something goes wrong. The copper ions in this formula make a direct difference in the speed and quality of metal plating. Missing this detail slows down troubleshooting and increases waste, which brings real costs in both time and resources.

Why Accuracy Matters with Chemical Formulas

I've seen mix-ups happen with lab orders, sometimes because folks grabbed chemicals with similar names but different formulas. Just one wrong atom in a compound can change outcomes. For copper pyrophosphate, using the wrong version might cause a plating bath to fail, leaving metal surfaces dull or flaky. The result isn’t just cosmetic. Poor adhesion or surface flaws can eventually lead to malfunctions, especially in electronics.

A mistake at this level puts product quality and safety on the line. In regulated industries—think electronics or medical devices—even a tiny fault in the copper layer causes recalls or puts users at risk. That’s the real-world reason for learning the exact formula and making sure everyone in the process, from supplier to technician, reads the label right and double-checks for accuracy.

Improving Handling and Safety

Regular training for staff makes a difference. I’ve worked beside people who took pride in knowing their chemicals, and they spotted contamination or label errors fast. Written protocols and checklists that include exact formulas, not just trade names, lead to fewer slips. It helps if management invests in clear storage systems, labeling, and up-to-date Material Safety Data Sheets.

Getting this right keeps workers safe, saves companies money, and ensures the products that leave the line meet their specs. By starting with the simple truth of the formula—Cu2P2O7—every step afterward stands a better chance of going smoothly. In each application, whether in research, industry, or education, the details matter, and knowing them is worth the effort. The right formula never sits on a shelf gathering dust. It keeps the whole operation running the way it should.

Copper Pyrophosphate in Everyday Use

Many industrial processes rely on copper compounds, and copper pyrophosphate plays a big role in fields like electroplating. People working in electronics, metal finishing, and circuit board manufacturing find copper pyrophosphate tough to avoid. Yet, most outside of these industries rarely cross paths with it. For those in the know, safety around any powdered chemical shapes daily routines on the shop floor.

Hazards: Not All Copper is Created Equal

A lot of folks hear “copper” and picture pennies or plumbing. Powders like copper pyrophosphate act much differently. It's a fine, light-blue solid — not something you want floating through the air. Getting it on your skin or in your eyes feels irritating, but real risk shows up when dust enters the air. Breathing it in brings copper into the body fast, bothering airways and lungs. Anybody with asthma or lung trouble reacts badly, and past exposures to copper dust can cause headaches, dizziness, and even leave a taste of metal in your mouth.

Toxic doesn’t always equal deadly, but copper overload brings harm. The human body needs copper in trace amounts for things like enzymes. Too much copper, even through chronic low-level exposure, can lead to liver and kidney issues. For workers, the route of greatest risk comes through inhalation or accidental ingestion due to poor hygiene or a sloppy workspace.

Reporting, Research, and Regulation

The toxicity of copper pyrophosphate looks different than the headline-grabbing hazards tied to lead or mercury. Still, research documents cases of workers developing respiratory illnesses and skin rashes. The U.S. Occupational Safety and Health Administration (OSHA) puts strict limits on “copper dust and mists” — including copper-containing salts like copper pyrophosphate. Allowed exposure levels sit low: OSHA recommends not exceeding 1.0 mg/m³ for copper dust and mists.

Studies in animals identify long-term high exposure, especially from ingestion, as a path to copper poisoning. Long-term buildup can affect the liver, cause anemia, or impact the central nervous system in severe cases. This makes regular monitoring and medical surveillance important for at-risk workers. There’s no real evidence that copper pyrophosphate itself is carcinogenic, but the overall impact on respiratory and digestive systems can’t be brushed off.

A Practical Approach to Workplace Safety

In my own experience, workshops that handle copper pyrophosphate run tighter ship than many casual observers expect. Fume hoods, personal protective equipment, and routine training keep the risks manageable. Shortcuts like skipping gloves or ignoring dust masks invite trouble, but seasoned crews rarely slip up more than once. Washing up before eating or drinking, and careful labelling, help prevent accidental ingestion — mistakes that catch up fast in the metal finishing business.

Modern industrial hygiene demands layers of control. Air monitoring for copper dust keeps workers and supervisors alert. Ventilation systems and routine surface cleaning make dust accumulation unlikely. Safety data sheets are required reading, and emergency responses drill muscle memory into regulars on the floor. Reporting symptoms early, such as coughs or rashes, means supervisors intervene before small problems bloom into medical emergencies.

Upgrading outdated processes or equipment usually pays for itself, not just in efficiency but in fewer missed days and medical costs. Industry keeps inventing new ways to reduce dust generation, automate dangerous steps, or recycle waste products safely. Solid regulations, informed management, and well-trained crews turn copper pyrophosphate from a lurking hazard into just one more workplace challenge that can be tackled head-on.

Why Storage Details Matter

Anyone who’s spent time in a laboratory or manufacturing floor knows copper pyrophosphate isn’t just another powder on the shelf. Even a small lapse in storage practices leads to serious headaches—contaminated solutions, unpredictable results, and risks to health. Years back, in a plating workshop, a leak in a container cost us hours in cleanup and spoiled an entire batch of product. Quality slips fast in the wrong environment.

This chemical picks up moisture from the air, so a tightly sealed container isn’t just helpful—it’s necessary. Humid conditions ruin copper pyrophosphate before it ever reaches a process tank. Simple desiccants, like silica gel sachets, make a noticeable difference. Investing in climate-controlled storage up front saves cash, time, and a lot of hassle down the line.

Handling Precautions Based on Real Experience

Nobody wants to dig powder out of an eye or take a deep breath of the dust. Safety glasses and dust masks seem like overkill until the day a small plume drifts up from a scoop. Lab coats or aprons keep copper stains off clothing, and gloves prevent any skin contact—a relief since some people develop rashes if they handle the stuff barehanded.

Copper pyrophosphate doesn’t explode or catch fire under normal conditions, so it's easy to get careless. But dust from bulk transfers or accidental spills requires proper cleanup, not just a quick sweep. Fine powder gets everywhere. Vacuuming with a HEPA filter, gentle damp cloths, and dedicated sweepers keep dust levels down. Ordinary brooms kick more up into the air, raising the risk of inhalation.

Minimizing Environmental and Personal Risk

Regulations on copper disposal aren’t just red tape—they exist for a reason. Rinsing leftover material into the sink builds up copper in pipes and eventually waterways, where aquatic life pays the price. Collecting all waste and sending it for proper treatment or recycling keeps operations above board and neighbors happy.

Emergency plans keep everyone on their toes. Spills happen, and every workplace should have clear steps: isolate the area, scoop up dry material, wash down residues with plenty of water, and notify a supervisor. Periodic drills make these steps second nature—panic never helps in a real spill.

Why Training and Labeling Matter

Clear, visible labels often get overlooked until local authorities pay a visit or a new employee grabs the wrong bag. Every container deserves a clearly written name, signal words, and hazard symbols. In my experience, well-marked supplies prevent mistakes late-night shifts, when attention dips and mistakes come easy.

All new hires benefit from a hands-on introduction—not just a page in the handbook. Experienced workers demonstrate proper transfer, labeling, and emergency response. This investment in training translates directly to fewer incidents and a safer atmosphere for everyone.

Smart Solutions for Better Safety

Switching to smaller packages cuts down on spillage. Bulk containers bring lower prices, but corners cut today become messes tomorrow. Custom scoops make transfers smoother, and antistatic mats stop powder from sticking to everything.

Routine inspections spot damage before it becomes a crisis. Cracks in containers, worn seals, or faded labels usually show up first on shelves that don’t get checked often. Assigning responsibility to specific people, rather than leaving it to “whoever’s there,” works better in the long run.

Proper care with copper pyrophosphate protects workers, saves money, and guarantees consistent results. Small steps in storage and handling pay off every day.

Electronics Manufacturing Drives Demand

Copper isn’t just for wires and coins. In electronics factories, copper pyrophosphate comes into play every day. If you’ve ever looked at a circuit board, you’re seeing copper its plating bath helped create. This compound supports the electroplating process, building thin copper layers across plastic or metal parts. Computer processors, smartphones, and tablets rely on copper finishes for both speed and durability. The rise of cloud computing and AI puts even more focus on building reliable electronics. Chip manufacturers push for higher efficiency, shrinking transistors to squeeze more power into spaces smaller than a fingernail. During plating, copper pyrophosphate allows for even deposition, which makes a direct difference in quality and lifespan of devices.

Printed Circuit Boards: Quiet Backbone of Modern Life

Printed circuit boards have turned from basic wiring frames into dense platforms for billions of devices. Copper pyrophosphate feeds the plating tanks that lay down conductive paths. These paths must deliver strong and stable current for years. Defective plating can start as a microscopic gap, then slowly grow, causing a phone, car, or pacemaker to fail without warning. This isn’t only inconvenient; it can be deadly in medical and automotive settings. I once saw a factory rework hundreds of boards after discovering staining and poor conduction—those failures cost time, money, and reputation. Using the right chemicals prevents headaches for everyone down the line.

Surface Finishing for Sustainable Tech

Renewable energy projects are not immune to technical problems. Wind turbines and solar inverters carry heavy loads. Their electronic controls depend on board finishes built with copper pyrophosphate plating. Poor plating can knock out power generation or monitoring, wasting clean energy and hiking maintenance costs. Real-world environmental challenges—humidity, dust, extreme temperatures—push electronic designs to their limits. Copper’s corrosion resistance lets gear survive longer in tough places, cutting waste and supporting green goals. The cost of downtime at a wind farm can reach thousands per hour, so using high-quality materials for reliable electronics truly matters.

Electroforming and Artistic Production

Decorative metalwork sometimes takes a technical turn. Jewelers, artists, and antique restorers work with copper pyrophosphate to add custom coatings and fine metal layers. Unlike simple copper plates, pyrophosphate baths allow more detailed features—needed for miniatures, trophies, or collector’s coins. This chemical helps craftspeople achieve smooth and bright home décor accents, museum-quality replicas, and even circuit-based wearables.

Quality and Safety: The Stakes Are High

The purity of copper pyrophosphate matters as much as the way it’s used. Impurities can cause failed batches or malfunctioning products. That risk pushes every supplier and buyer to test carefully and track lots. The International Organization for Standardization and the European Union set guidelines to keep safety high, especially for sensitive industries like aerospace and healthcare.

Problems and Solutions

Using copper pyrophosphate demands diligence. Exposure risks for workers crop up during handling, so automation and training help keep workplaces safe. Wastewater from plating tanks can damage local waterways. Most responsible companies invest in treatment systems that extract metals before water leaves the building. As cities push for greener operations, companies look for ways to reclaim copper from spent solutions, recycling back into production and cutting environmental impact.

Real Progress Starts with Smart Choices

Reliable electronics, safe infrastructure, and beautiful art share a common thread. The chemicals behind the scenes, like copper pyrophosphate, shape the world in ways most people never see. Attention to sourcing, safety, and recycling can help companies build better products, protect people, and respect the planet. The impact of these decisions touches every device, car, and piece of tech we use each day.

| Names | |

| Preferred IUPAC name | Copper(II) diphosphate |

| Other names |

Dicupric pyrophosphate

Copper(II) pyrophosphate Pyrophosphoric acid copper(2+) salt |

| Pronunciation | /ˈkɒpər paɪ.rəˈfɒs.feɪt/ |

| Identifiers | |

| CAS Number | [5893-66-3] |

| Beilstein Reference | 1563772 |

| ChEBI | CHEBI:53411 |

| ChEMBL | CHEMBL3305022 |

| ChemSpider | 53638436 |

| DrugBank | DB11348 |

| ECHA InfoCard | 03b43c1e-24a1-498b-8c10-4fae90d55f7e |

| EC Number | 237-930-3 |

| Gmelin Reference | 11416 |

| KEGG | C18326 |

| MeSH | D003822 |

| PubChem CID | 24857133 |

| RTECS number | ZK9810000 |

| UNII | V45RQ3A34V |

| UN number | UN3260 |

| CompTox Dashboard (EPA) | DTXSID4020849 |

| Properties | |

| Chemical formula | Cu₂P₂O₇ |

| Molar mass | 285.6 g/mol |

| Appearance | White powder |

| Odor | Odorless |

| Density | 2.90 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -4.80 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 10.5 |

| Basicity (pKb) | 11.5 |

| Magnetic susceptibility (χ) | −47.6×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.651 |

| Viscosity | Viscous liquid |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 169.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −1562 kJ/mol |

| Pharmacology | |

| ATC code | V03AB05 |

| Hazards | |

| Main hazards | May cause irritation to the eyes, skin, and respiratory tract. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| Precautionary statements | P260, P264, P270, P272, P273, P301+P312, P330, P314, P391, P501 |

| NFPA 704 (fire diamond) | 1-0-3-W |

| Lethal dose or concentration | LD50 (oral, rat): > 2,000 mg/kg |

| LD50 (median dose) | LD50 (median dose) for Copper Pyrophosphate: "Oral, rat: >2000 mg/kg |

| NIOSH | TT4200000 |

| PEL (Permissible) | 1 mg/m³ |

| REL (Recommended) | 2~8°C |

| IDLH (Immediate danger) | IDLH: 100 mg/m³ |

| Related compounds | |

| Related compounds |

Copper sulfate

Pyrophosphoric acid Potassium pyrophosphate Ammonium pyrophosphate Sodium pyrophosphate |